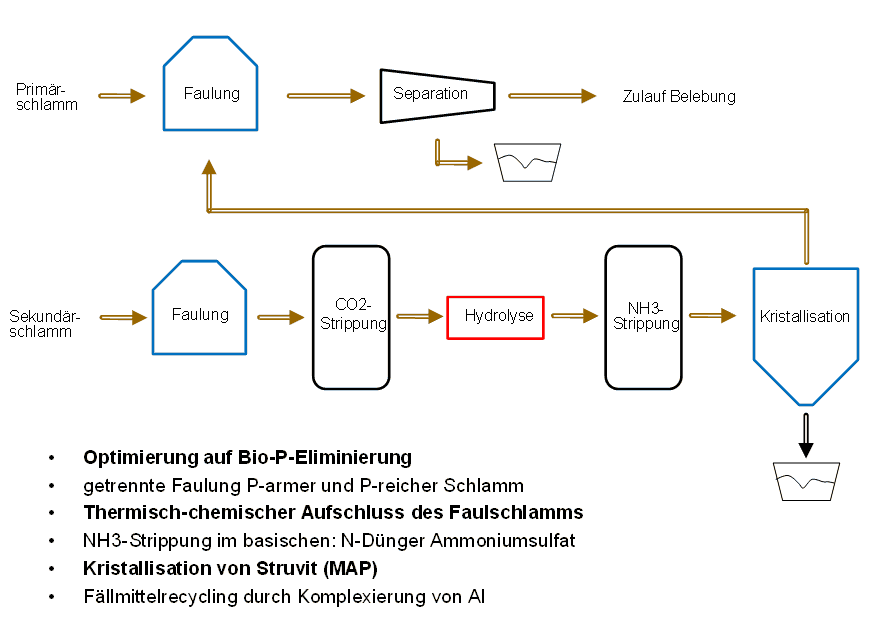

Normally, the primary sludge from primary clarification is fed together with the excess sludge from secondary clarification to a joint anaerobic sludge treatment process. As the excess sludge contains around 90 % of the phosphorus from the wastewater treatment plant’s influent and only accounts for around 40 % of the total sludge volume, it makes sense to use this sludge fraction separately for phosphorus recovery in the future.

Features of the phosphorus recycling process are

- Decentralized process

- Holistic approach to nutrient recovery (P and N) and sludge treatment

- Sewage sludge can be utilized flexibly

- Acceptance of external sludge possible

- Production of a directly usable fertilizer

- Increase in gas yield by 15% through fixed bed reactor and TDH

- Reduction in the amount of sewage sludge by 10 – 15%

- Savings on precipitants (approx. 2/3) and polymer (approx. ½)

- Energy consumption at wastewater treatment plants in PS decreases, own energy generation increases

- MAP precipitation in the system virtually impossible (decanters, pipes, tanks)

- PO4-P effluent target values of 0.5 mg/l to 0.3 mg/l are possible and economically feasible.

- A favorable nutrient ratio in the wastewater through N reduction and the addition of citric acid for the aluminum recycling process can be expected to improve the effluent values

- Optimal “harvesting conditions” for Bio P sludge can be realized

- The required criteria >50% recovery rate, or 20g PO4-P/kg DM are met.

- The result is a high-quality MAP fertilizer with a very low heavy metal load