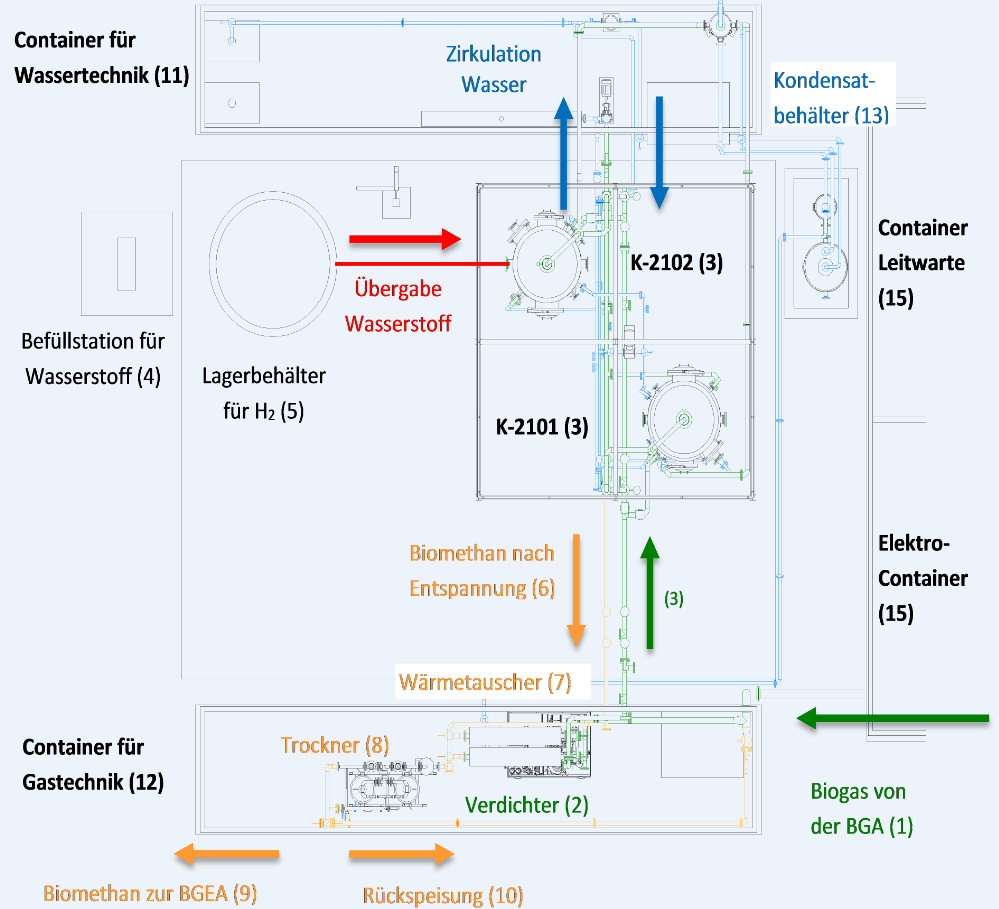

On the basis of various research and development projects on biological methanation, great progress has already been made towards the market launch of the technology. This concerns both the development of new, flexible electrolysers and the use of new types of bioreactors, as well as the optimization of potential production strains. In addition, PFI-Bioraffinerietechnik GmbH has carried out process optimizations with regard to electricity and heat management in order to reduce internal energy requirements and minimize conversion losses.

Features of the power-to-gas technology are:

- Utilization of 90 % of the total energy in the biogas as usable heat, CNG (as fuel), methane gas (as storage medium) and for electricity production

- Development of a plant configuration for flexible energy use

- Provision of water for hydrogen production by electrolysis with surplus electricity

- Use of biogas carbon dioxide for the methanation of renewable hydrogen

- Adaptation of the electrolysis plant for use with P2X

- Use of waste heat for fertilizer production from fermentation residue

- Preparation for the coupling of synthesis gas into the BGAA

- Combination of biotechnological methanation with other biogas purification processes (pressurized water scrubbing, membrane adsorption, etc.)